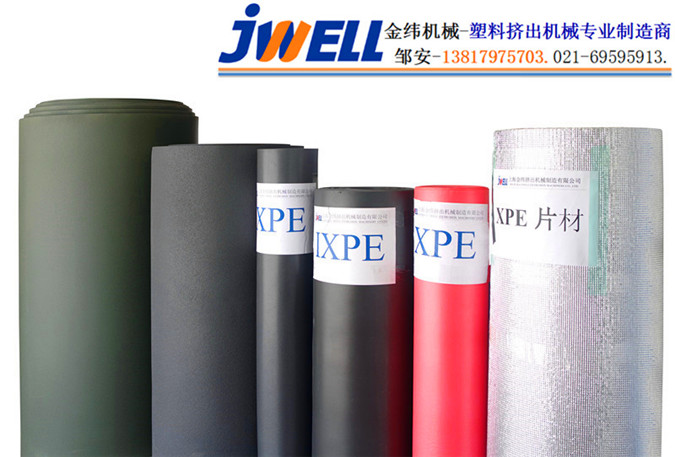

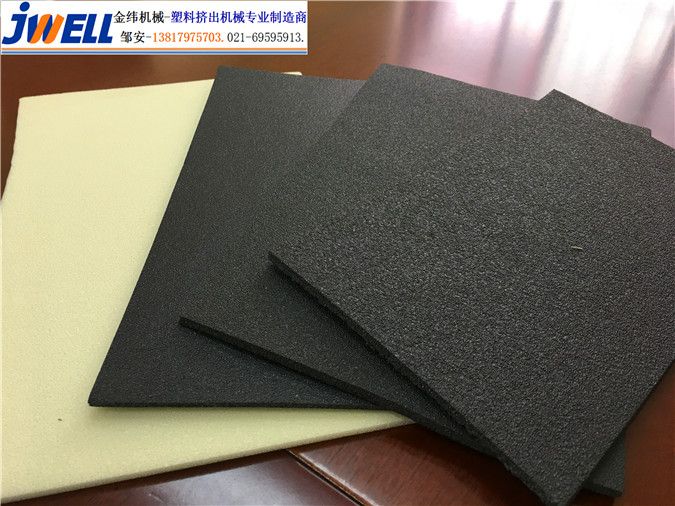

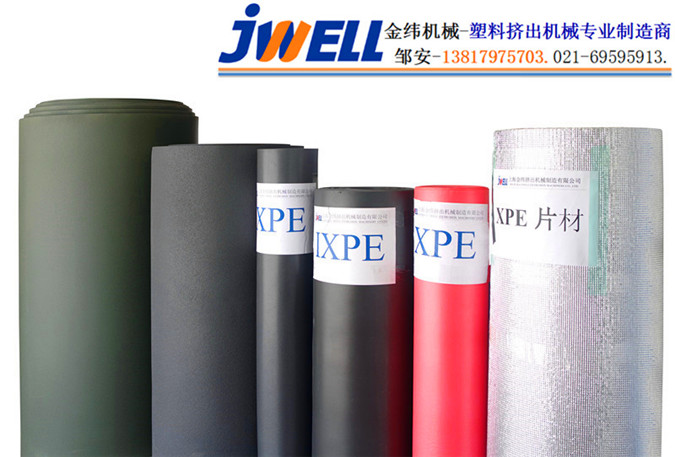

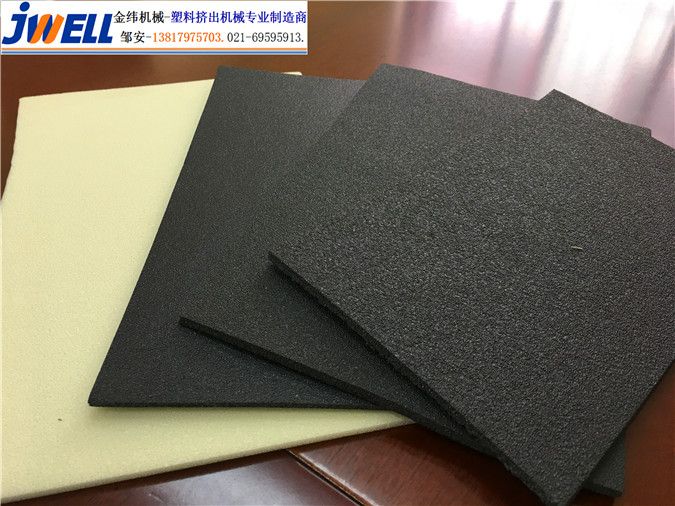

XPE 发泡材料为一种独立闭孔材料,不仅具有良好的隔热、保温功能,而且表面光洁、防水、降低噪音、阻燃,广泛用于汽车缓冲绝热、空调保温、

管道工程、高档复合屋面保温隔音系统、箱包内衬、体育休闲用品、装饰材料等领域。

IXPE 辐射交联发泡片材,为化学交联发泡片材,表面更为平整、泡孔细密均匀、各项物理性能都优于XPE,广泛应用于建筑、化工管道、热力工

程、车船制造、包装行业、体育娱乐等行业。目前该产品在中国内地处于市场的成长期,发展潜力巨大。

XPE foam material as a separate closed cell material,Not only has good thermal insulation, heat preservation function, and the surface

must be smooth, waterproof, low noise, flame retardant, Buffer is widely used in automobile, air conditioning heat preservation, duct

Insulation ,Premium composite roofing Insulation systems, Luggage liners, sports leisure supplies, decoration materials and other fields.

IXPE radiation crosslinked foamed sheet, for the chemical crosslinked foam sheet, A more smooth surface, uniform foam fine, the physical

properties are better than the XPE,Widely used in construction, chemical piping, thermal engineering Vehicle manufacturing, packaging,

sports and entertainment industries.At present the products in the mainland of China in the period of market growth, development

potentiality is enormous.

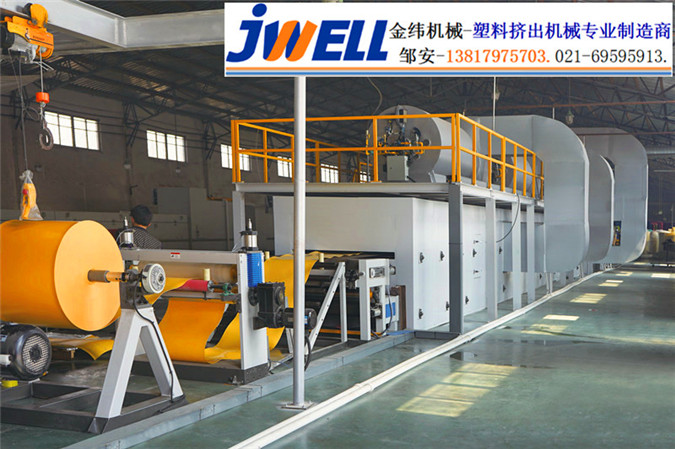

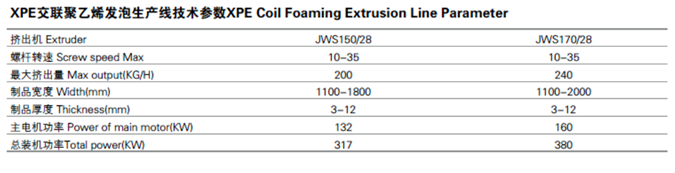

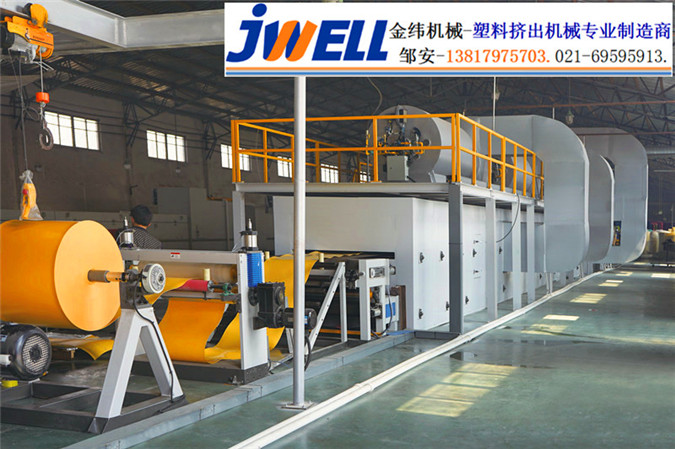

X P E 交联聚乙烯发泡卷材线包含以下四步生产流程:

造粒- - - - 挤出母片- - - - 发泡成型- - - - 辅机收卷

一、常见的三种造粒方式:

1、密炼-- 开炼-- 拉片-- 冷却-- 切粒

2、密炼-- 单螺杆挤出-- 水环(风冷)切粒

3、高速搅拌机-- 平双挤出机-- 单螺杆挤出机-- 水环(风冷)切粒

二、挤出母片:

上海金纬根据多年XPE 螺杆设计制造经验,不断地改进XPE 螺杆的结构设计,改进机筒以及螺杆的温控和冷却系统,对模具的内部结构优化

设计,采用立式镜面三辊压光机成型,配备高精度的恒温系统,使得XPE 母片材挤出过程中稳定连续,确保物料塑化分散均匀,温度易于控制。

三、发泡成型:

发泡炉采用新型三段加长炉,炉体分为预热段、交联段、发泡段三部分,炉体全长23 米,高5.5 米,宽3.5 米。

配置名牌高精度节能燃烧器,确保温度得到精确控制,可生产XPE、IXPE,橡塑发泡产品。

本炉三大特点:

1、能耗低:将预热段、交联段做了较大改变,满足工艺要求的情况下,减少热容空间,节能降耗。,燃气用量与两段炉相当。

2、生产工艺范围宽:炉内热量分布上,克服韩国炉体内热量分布不合理的缺陷,按照XPE 发泡的工作热量要求,使得XPE 发泡在一个比较宽

的范围内,发泡倍率在5-35 倍,发泡充分,连续稳定。

3、产量大:在目前国内生产的发泡炉中,我们的三段炉产量最大,最大200KG/H 以上,而且XPE 泡孔比两段炉更细密。

四、收卷辅机

辅机全长20 米,依次通过五辊定型机、风冷系统、表面整形、自动纠偏切边装置、牵引机、双工位收卷机。

以上挤出母片、发泡成型、收卷辅机三部分全长60 米左右。

XPE crosslinked foamed PE roll material line contains the fololwing four - step process :

pelletizing---extrude---- foaming ----winder

ONE、Normal pelletizing method:

1.Banburying ---open mill --zipper pulls---cooling --cutting

2.Banburying---single screw extruder --water circulation (or air cooling)cutting

3.High speed blender--parallel twins screw extruder---single screw extruder--water circulation (or air cooling)cutting

TWO、Extrude

Shanghai Jwell screw design and manufacture based on XPE experience,Continuously improve the structure of XPE screw design, improved barrel and

screw temperature control and cooling systems,On inner Structural Optimization Design of mould,Formed with vertical mirror of three - roll calender,

equipped with high precision temperature control system,Mother makes XPE steady and continuous process of sheet extrusion, ensure the material plasticizing

distributed evenly, easy to control the temperature.

THREE、Foaming

Foaming oven adopts the latest enhanced furnace ,Oven divided into three parts: preheating stage,coil stage , furnace whole length 23meters, high ceiling

5.5 meters, width 3.5 meter.,equipped imported brand high precise burner,Ensure accurate temperature control, can produce XPE, IXPE, rubber and foam

products

The furnace three major characteristics :

1, low energy consumption :

the preheating period, crosslinking made larger changes, meet the technological requirements, reduce the heat capacity of space and energy consumption. ,

gas consumption and a two - stage furnace.

2, wide range of production processes :

Heat distribution in the furnace, overcome the defects of South Korea's unreasonable distribution of heat in the furnace,

In accordance with the work of the XPE foam thermal requirements, making the XPE foam over a relatively wide range, expansion ratio at 5-35 times, foam

full, continuous and stable.

3, the output is big : In the current domestic production of foam furnace, our three - stage production of the largest and the largest 200KG/H above, and XPE

foam more detailed than the two - stage gasifier.

Four, rewinding auxiliary equipment

The whole length of downstream line is 20m, as from front to back order, it is passed 5 roller calibration unit,air cooling system,smooth surface dealing

device,automatic correction trimming device,haul off unit,double position collector.

The above three parts, foam extrusion, rolling length of 60 meters.

地址:上海市嘉定区黄渡镇春意路111号

地址:上海市嘉定区黄渡镇春意路111号 电话:021-69595913

电话:021-69595913 邮箱:salfb@jwell.cn

邮箱:salfb@jwell.cn